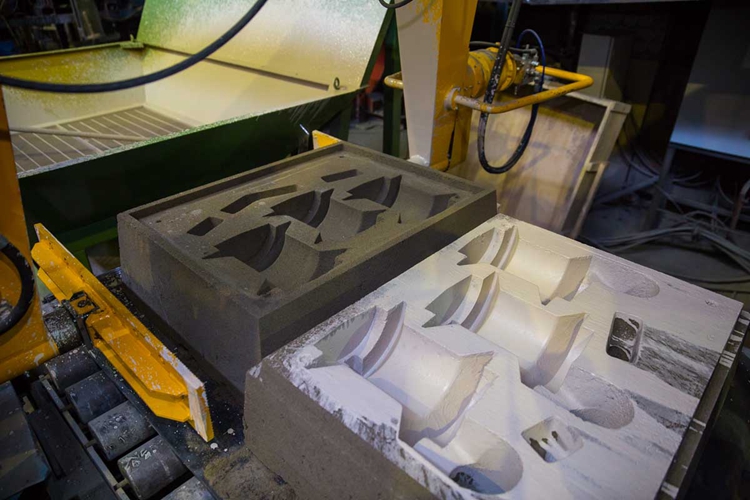

Z149WKJolt-Squeeze-Sand-Mould-Machine-Foundry-Green-Sand-Moulding-Casting-Equipment

Model Z149WK

Products

Products DETAILS

Z149WKJolt-Squeeze-Sand-Mould-Machine-Foundry-Green-Sand-Moulding-Casting-Equipment

| NameModel | Z143W | Z145WB | Z146WK | Z147WK | Z148WB | Z148WK | Z149WK |

| Sand box inner dimensions(mm) | 500*400 | 550*450 | 600*500 | 800*600 | 800*600 | 1000*630 | 1050*930 |

| Work surface size(mm) | 560*420 | 600*550 | 700*550 | 800*575 | 900*730 | 1200*730 | 1200*1030 |

| Shock load(kgf) | 200 | 300 | 400 | 400 | 600 | 1200 | 1200 |

| Compacting strength(kgf) | 4200 | 6300 | 7500 | 8000 | 10000 | 16000 | 16000 |

| Ejection stroke(mm) | 160 | 180 | 200 | 220 | 250 | 250 | 350 |

| productivity(Box/h) | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 |

Vibration modeling in ordinary machine modeling has low vibration frequency, large amplitude, low production efficiency and high noise. In order to overcome the shortcomings of vibration modeling, the vibration frequency of this machine is about 10 times higher than that of vibration modeling, and the amplitude is about 1/10. Another modeling method - micro-vibration machine modeling is used. The principle of micro-vibration molding machine is shown in the figure. The compressed air enters the micro-vibration cylinder and pushes the micro-vibration piston to drive the template and sand box on the workbench to rise together. The compressed air also makes the micro-vibration cylinder move downward and compresses the spring under the bottom of the cylinder; when the micro-vibration piston rises to a certain height, The exhaust hole opens, the air pressure in the cylinder decreases rapidly, the fretting piston drops rapidly under the action of gravity, and the fretting cylinder rises rapidly due to the restoring force of the bottom spring, and the molding sand is tightened under the impact of the fretting piston and the fretting cylinder. Solid, and after repeated impacts in a short period of time, the sand mold reaches the required compactness.

Micro-vibration molding has high specific pressure, uniform compactness, low noise, high production efficiency, good casting quality and wide adaptability, and has been widely used in automated casting production.