Micro-vibration compaction molding machine for casting,Z148WK

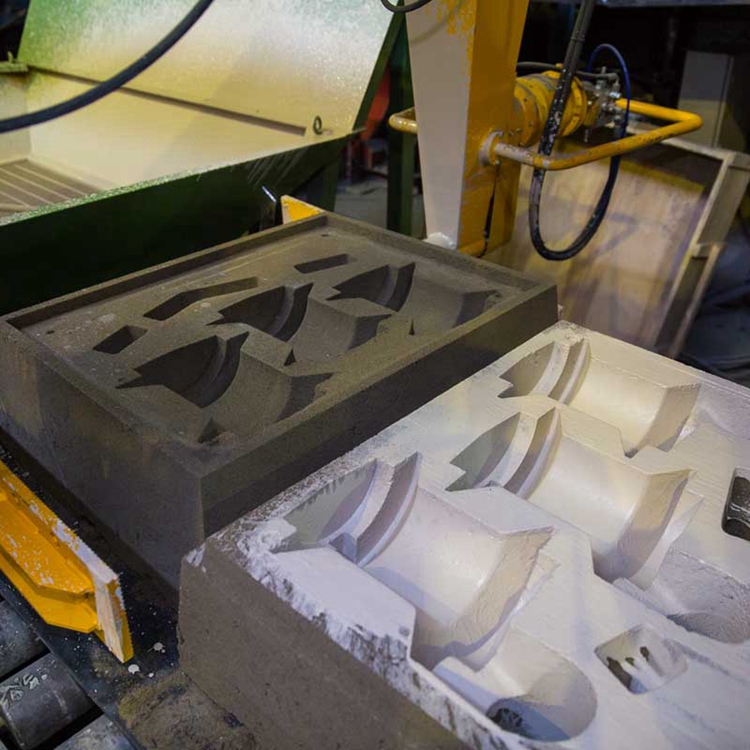

Sand Moulding Making,Green Sand Casting Technology

Model Z148WK,clay sand moulding molding machine,green sand molding process

Products

Products DETAILS

Micro-vibration compaction molding machine for casting,Z148WK

| NameModel | Z143W | Z145WB | Z146WK | Z147WK | Z148WB | Z148WK | Z149WK |

| Sand box inner dimensions(mm) | 500*400 | 550*450 | 600*500 | 800*600 | 800*600 | 1000*630 | 1050*930 |

| Work surface size(mm) | 560*420 | 600*550 | 700*550 | 800*575 | 900*730 | 1200*730 | 1200*1030 |

| Shock load(kgf) | 200 | 300 | 400 | 400 | 600 | 1200 | 1200 |

| Compacting strength(kgf) | 4200 | 6300 | 7500 | 8000 | 10000 | 16000 | 16000 |

| Ejection stroke(mm) | 160 | 180 | 200 | 220 | 250 | 250 | 350 |

| productivity(Box/h) | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 |

The following products are suitable for wet sand molding machines: engine parts,pump bodies, valves, auto parts

, railway vehicle parts, pressure vessels, fan blades, mechanical parts, automobile hubs, gearbox housings, steel components, aviation parts, agricultural machinery parts, water pump housings, mining machinery parts, power equipment parts, Oil drilling equipment parts, aluminum alloy parts, copper alloy parts, industrial valve parts

, these are common product types of green sand molding machines in the casting field. The specific application also depends on customer needs and specific production processes.

Green sand molding machines have many advantages that make them widely used in the foundry industry. Here are some of the key advantages of green sand molding machines: High Precision: Green sand molding can provide high-precision casting molds that help in the production of precision parts.

Good surface quality: Molds made by green sand molding machines produce smooth and high-quality casting surfaces.

Suitable for various alloys: Suitable for casting various metal alloys, including iron, aluminum, copper, magnesium, etc.

High production efficiency: Compared with other casting methods, the green sand molding machine has high production efficiency and can quickly make molds.

Flexibility: Strong adaptability, suitable for the production of castings of different shapes and complexities.

Reusability: The mold can be used multiple times, reducing molding costs.

Environmentally friendly: Compared to some other casting methods, green sand molding is relatively environmentally friendly because it does not require large amounts of chemical additives.

Easy to operate: Operation is relatively simple and does not require a highly skilled operator.

Suitable for mass production: Suitable for large-scale and batch production, improving production efficiency.

Controllable molding process: The molding process is highly controllable, helping to ensure consistent product quality.

These advantages make green sand molding machines a popular production process in the foundry industry.