Sand coated iron mould- Buy crankshaft casting line

Model TFS-60 series-FOB price99000-200000 USD/set

Products

Products DETAILS

Sand coated iron mould- Buy crankshaft casting line

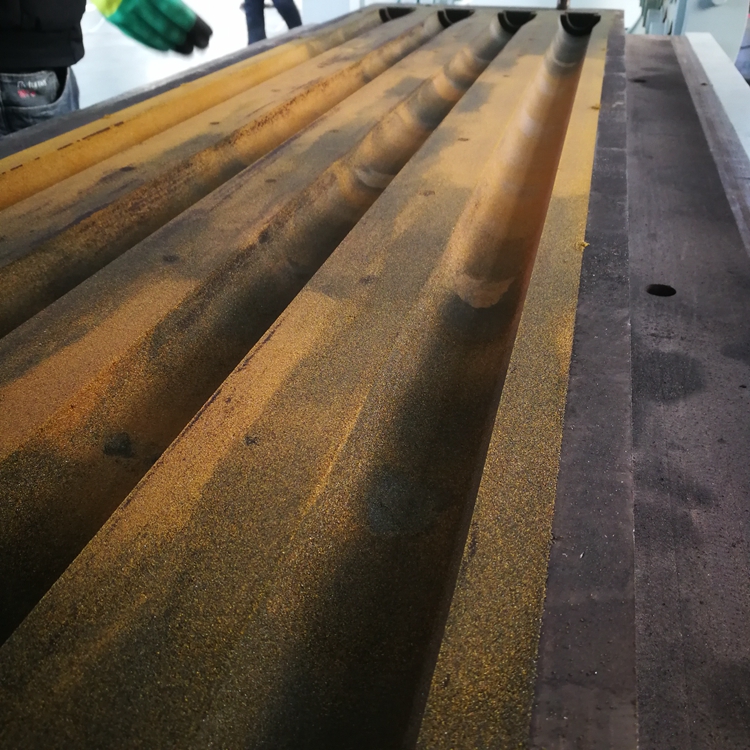

Through the above process, the liquid metal solidifies in the iron mold.

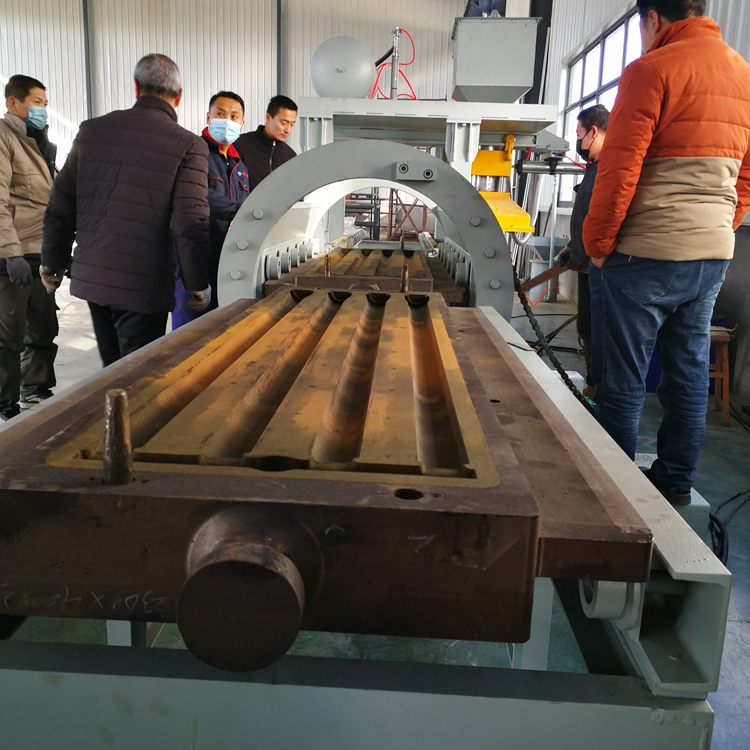

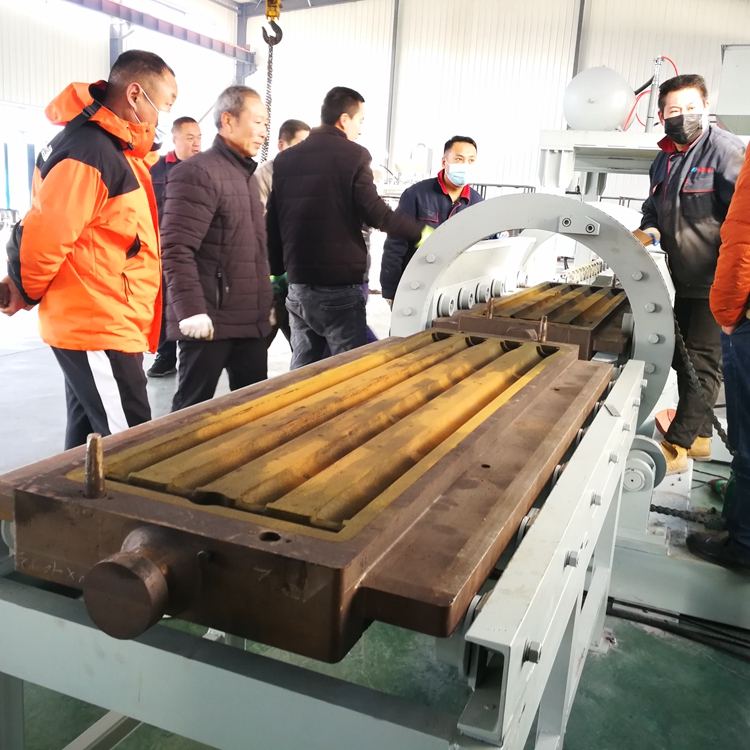

1) Iron sand coating production line model: TFS-60

2) Driving mode: pneumatic or hydraulic;

3) Power supply/voltage/rated power: 380V/50Hz; 75kW

4) Overall size of the production line: covering an area of approximately 280 square meters.

5) Action mode: PLC human-machine interface intelligently controls the entire line of actions and synchronizes manual control.

6) Production line operator labor: 2-4 people.

7) Operation rhythm: no-load operation rhythm is about 40"; production rhythm: 60~80"/box (45~60 boxes/hour).

8) Single line annual production capacity: 5,000-12,000 tons.

9) Scope of application: 40~150 chromium series alloy cast balls, gray cast iron, ductile iron, cast carbon steel, cast alloy steel, cast stainless steel, brass/copper-based alloys, drive shafts, camshafts, torque rods, profiles, crankshafts , production of high silicon cast iron anodes, CADI casting balls and some small and medium-sized castings.

10) Standard configuration of molds: 60 sets of molds of a single specification.

11) Standard template: one pair of templates for each specification (one set of upper and lower templates).

12) Nozzle configuration: 1 set for each specification (1 set for upper and lower molds).

Features of multi-station sandblasting machine

4. Multi-station core-shooting board cleaning, unobstructed visual inspection of the pattern board, easy inspection, thorough removal of residues to ensure the quality of sand coating

The multi-station core shooting machine can realize that there is no need to wait for curing time after sand coating;

1. Can produce two products with similar specifications while improving equipment operation rate;

2. By adding one more station to the original one, the output can be increased by 40%;

3. Two specifications of products can be produced at the same time, saving 50% of mold investment;