ZH86 series fully automatic double-station hot core box core shooting machine

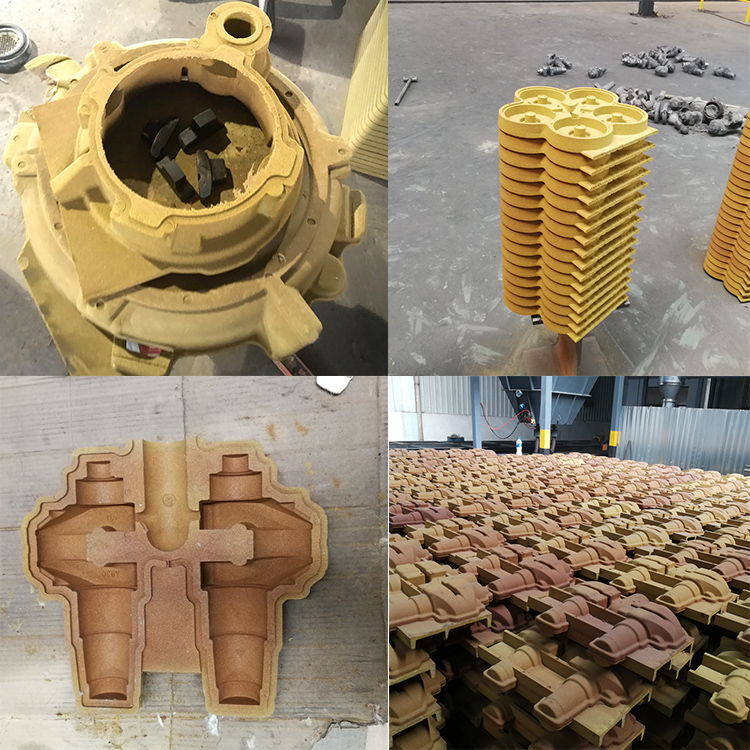

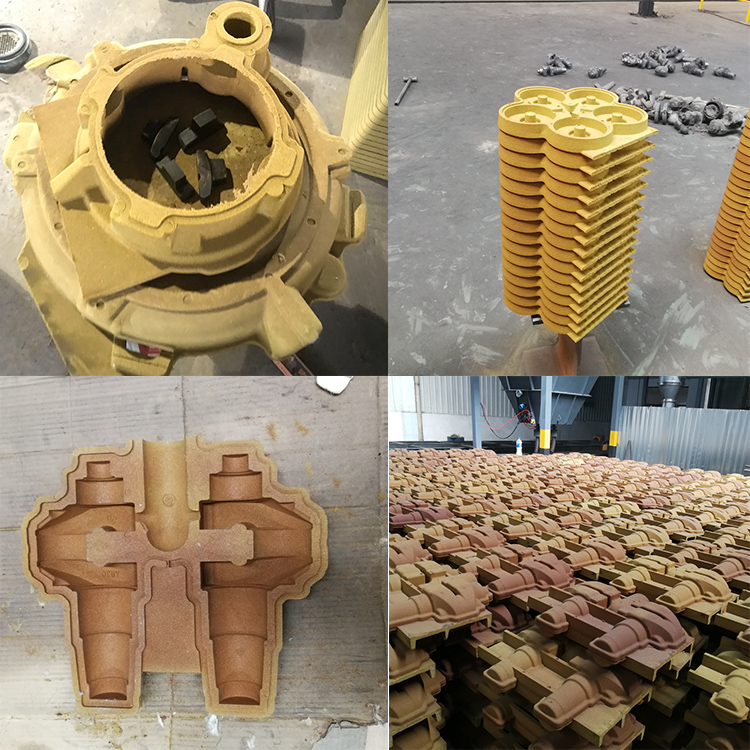

It has been widely used in foundry workshops in automobiles, parts, engines, various valves, power accessories and other industries.

Model Z86 series

Products

Products DETAILS

ZH86 series fully automatic double-station hot core box core shooting machine

| project | Z8610BF | Z8613B | Z8613BF | Z8615B | Z8615BF | Z8616BF | Z8618B |

| Template size (mm) | 620*300 | 660*330 | 920*320 | 620*400 | 680*420 | 760*460 | 900*600 |

| Maximum core weight (KG) | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Sand bucket volume (KG) | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| heating method | Electric heating | Electric heating | Electric heating | Electric heating | Electric heating | Electric heating | Electric heating |

| Electric heating power (KW) | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| System pressure (Mpa) | 0.55-0.65 | 0.55-0.65 | 0.55-0.65 | 0.55-0.65 | 0.55-0.65 | 0.55-0.65 | 0.55-0.65 |

| Operation method | Manual/Single Week | Manual/Single Week | Manual/Single Week | Manual/Single Week | Manual/Single Week | Manual/Single Week | Manual/Single Week |

| Product Name | Core Shooting Machines | ||

| Applied to wach material | casting, metal parts, profiles etc | ||

| Applicable industry | machinery, foundry, forging, mechanical and steel industry | ||

| function | production sand mould | ||

| Voltage | 380V/50HZ or 220V/60HZ | Warranty | One year |

| Power | Electricity | Certificate | ISO 9001 |

| Model | Z86 series | PLC | Siemens,Omron |

| Productivity | Customized | Low voltage | Schneider |

| Condition | New | Brands | XiangMao |

| Color | Customized | Size | Customized |

| Cleaning method | Automatic | Electrical control system | Auto-detection, auto-alarm and auto-cutout. |

| Material | Metal/coil | Origin | Shangdong, China |

| Cleaning material | Shot steel/shot grit/wire cut etc | After-sales service | Engineers available to service machinery |

| If you have any question or concerns. pls feel free to contact us. | |||

The hot core box core shooting machine uses coated sand to shoot sand cores. Can be shot within various template size ranges and within the maximum shot sand weight range

Solid sand core. This machine involves two shooting heads that use the sand shooting barrel to move back and forth in a straight line to complete the sand adding and sand shooting actions. According to different user molds, the two shooting heads can

It can operate simultaneously or individually. It can place two different molds at the same time, or place one different mold on one side for production.

The optimized design and installation core box template uses three through-type guide shafts and one semi-guide shaft, which further increases the stability of the equipment, facilitates core extraction, and is more user-friendly. Book

All movements of the equipment are automatically controlled by PLC. The operation is convenient and fast, and the productivity is high. Hot core box peritoneal sand is used to ensure the quality of the sand core. This machine opens and closes the mold

The method is vertical splitting, which can be set to fix the mold in the middle and open and close the mold left and right. There is a set of mold opening and closing cylinders on the left and right sides of the movable mold, and two sets of molds can be installed respectively.

Close the mold left and right to complete. When the mold is opened in place and hits the dead ejector pin, the sand core is ejected.