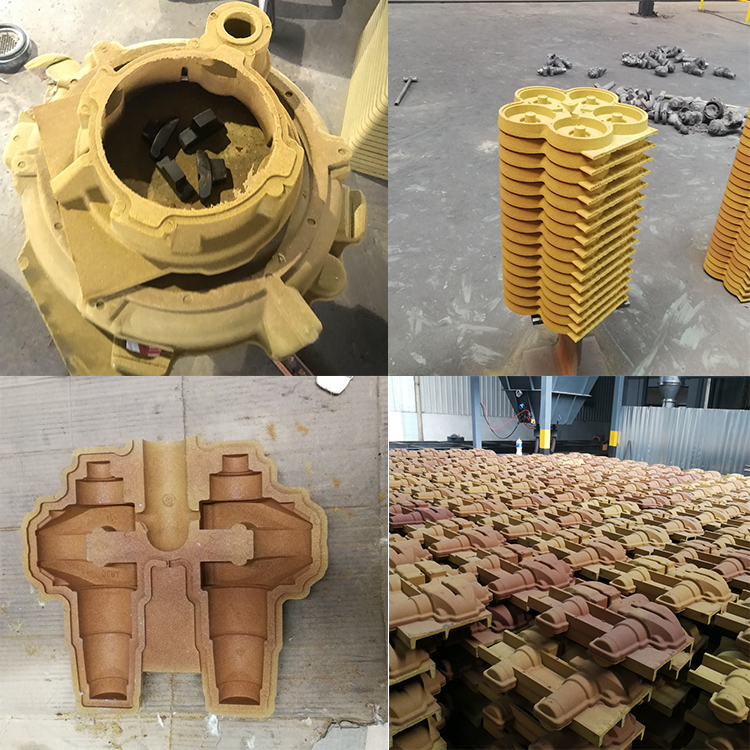

Casting sand shell forming machine

Model Z86 series

Products

Products DETAILS

Casting sand shell forming machine

|

project |

Z8610BF |

Z8613B |

Z8613BF |

Z8615B |

Z8615BF |

Z8616BF |

Z8618B |

|

Template size (mm) |

620*300 |

660*330 |

920*320 |

620*400 |

680*420 |

760*460 |

900*600 |

|

Maximum core weight (KG) |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

|

Sand bucket volume (KG) |

200 |

200 |

200 |

200 |

200 |

200 |

200 |

|

heating method |

Electric heating |

Electric heating |

Electric heating |

Electric heating |

Electric heating |

Electric heating |

Electric heating |

|

Electric heating power (KW) |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

System pressure (Mpa) |

0.55-0.65 |

0.55-0.65 |

0.55-0.65 |

0.55-0.65 |

0.55-0.65 |

0.55-0.65 |

0.55-0.65 |

|

Operation method |

Manual/Single Week |

Manual/Single Week |

Manual/Single Week |

Manual/Single Week |

Manual/Single Week |

Manual/Single Week |

Manual/Single Week |

| Product Name | Core Shooting Machines | ||

| Applied to wach material | casting, metal parts, profiles etc | ||

| Applicable industry | machinery, foundry, forging, mechanical and steel industry | ||

| function | production sand mould | ||

| Voltage | 380V/50HZ or 220V/60HZ | Warranty | One year |

| Power | Electricity | Certificate | ISO 9001 |

| Model | Z86 series | PLC | Siemens,Omron |

| Productivity | Customized | Low voltage | Schneider |

| Condition | New | Brands | XiangMao |

| Color | Customized | Size | Customized |

| Cleaning method | Automatic | Electrical control system | Auto-detection, auto-alarm and auto-cutout. |

| Material | Metal/coil | Origin | Shangdong, China |

| Cleaning material | Shot steel/shot grit/wire cut etc | After-sales service | Engineers available to service machinery |

|

If you have any question or concerns. pls feel free to contact us. |

|||

Core sand is injected into the core box at high speed, causing a limited volume of compressed air to suddenly expand. The filling process is therefore associated with a certain compaction of the mold material. Depending on the program, both wet and dry mold materials can be injected into cold or hot core boxes. The following takes core making using the cold core box process as an example to illustrate the working principle of the core shooting machine: After the machine chamber is prepared, the mold materials are fed in. It is then shot into a core box. The core box is hydraulically clamped to prevent the core box from moving during injection and inflation. The clamping and detaching devices can be changed so that the core box can be used both vertically and horizontally. The mold material is injected by the injection device and pressed on the core box, and then the hardening device is brought in to perform the hardening process. Then the separation process begins. Turning the movable part of the core box pushes the core out of the solid core box part onto the conveyor belt (film). Forming tools can be made of wood, plastic or metal. The choice of material depends on the size of the collection. The bleeder plate must be well-sealed and constructed so that the hardening gas can penetrate evenly into all areas of the core. Ventilation openings must be installed in the core box to ensure good, even ventilation of the core material. The larger the ventilation cross-section, the lower the flow resistance when deflating and the faster the core hardens. The core box should be constructed in such a way that the ventilation cross-section (core box vent) covers 3 to 5% of the core box surface.

The working principle of a core shooting machine involves using high-pressure gas or mechanical force to eject sand core material into a mold to form the desired shape of the core. This usually involves specific sand core materials being mixed and sprayed into a core disk or mold, which is then cured and processed to form a strong core. Mold Structure: Core shooters typically include a core disk or mold that has the desired core shape. The sprayed sand core material fills the mold and forms the desired internal structure. Sand core material: A special sand core material is usually used, such as green sand, dry sand or chemically hardened sand, etc., depending on the specific casting requirements and the nature of the workpiece. Applicable industries: Core shooting machines are widely used in the metal casting industry, including casting cast iron, cast steel, aluminum alloy and other metal workpieces.