Casting sand shell forming machine,Core shooting machine

Model Z8616BF -FOB price 8,800 USD/set

Products

Products DETAILS

Casting sand shell forming machine,Core shooting machine

| project | Z8610BF | Z8613B | Z8613BF | Z8615B | Z8615BF | Z8616BF | Z8618B |

| Template size (mm) | 620*300 | 660*330 | 920*320 | 620*400 | 680*420 | 760*460 | 900*600 |

| Maximum core weight (KG) | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Sand bucket volume (KG) | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| heating method | Electric heating | Electric heating | Electric heating | Electric heating | Electric heating | Electric heating | Electric heating |

| Electric heating power (KW) | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| System pressure (Mpa) | 0.55-0.65 | 0.55-0.65 | 0.55-0.65 | 0.55-0.65 | 0.55-0.65 | 0.55-0.65 | 0.55-0.65 |

| Operation method | Manual/Single Week | Manual/Single Week | Manual/Single Week | Manual/Single Week | Manual/Single Week | Manual/Single Week | Manual/Single Week |

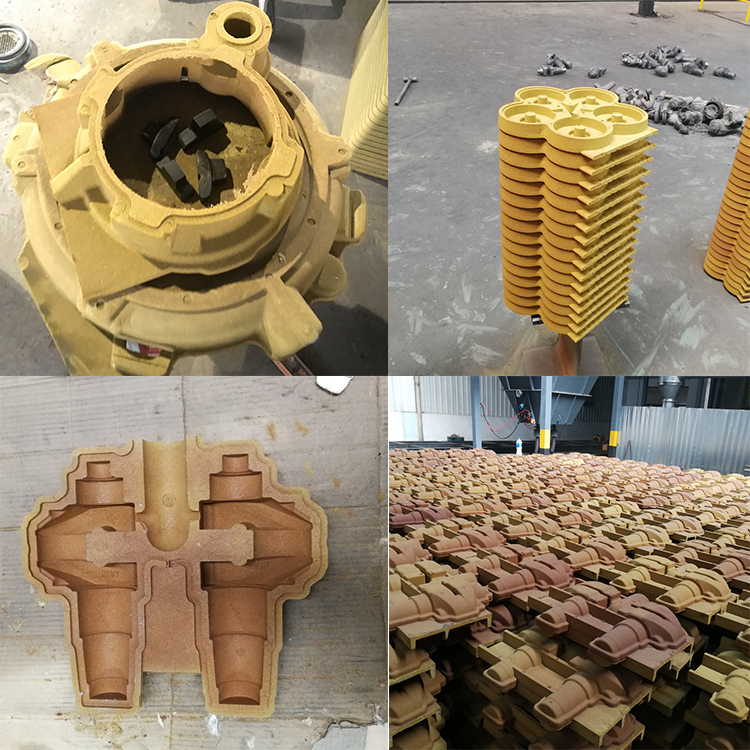

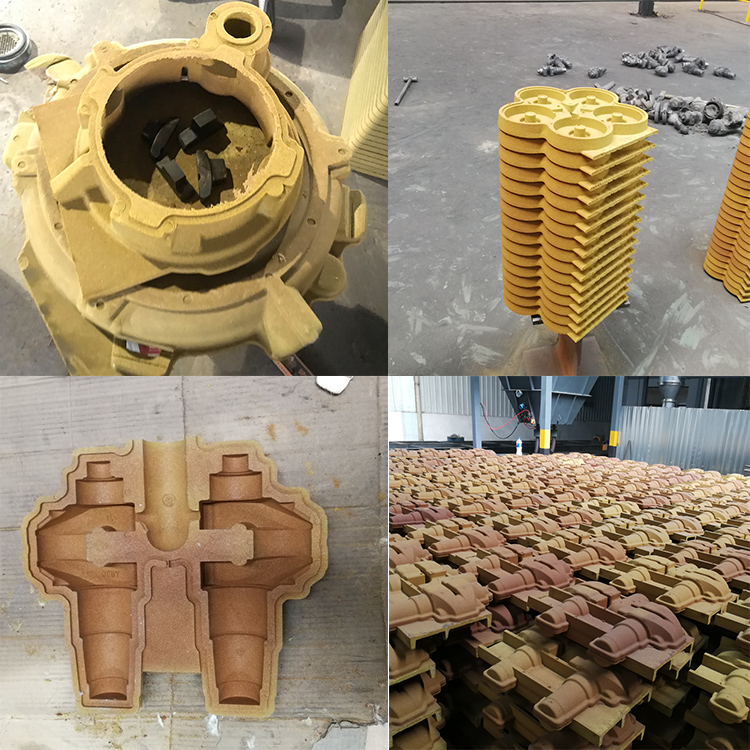

Casting sand shell forming machine is a device used to make casting molds, usually used in the foundry industry. The following are the general features and application range of casting sand shell forming machines:

Features:

Automated production: Casting sand shell forming machines are usually designed as automated production lines, which can efficiently complete the sand shell making process.

High-precision mold making: High-precision, high-quality casting molds can be made to ensure the size and surface quality of the final casting.

Flexibility: It has certain flexibility and can adapt to the production needs of castings of different shapes and sizes.

Save human resources: The high degree of automation reduces dependence on manpower and improves production efficiency.

Saving materials: The use of precise mold production reduces the waste of materials such as sand and improves resource utilization efficiency.

Fast production cycle: Compared with the traditional manual mold making method, the casting sand shell forming machine can complete the production cycle more quickly, improving production efficiency.

Programmable control system: Equipped with an advanced programmable control system, it can flexibly adjust parameters to adapt to the production requirements of different castings.

Scope of use:

Foundry industry: Casting sand shell forming machines are mainly used in the foundry industry to produce various metal castings, such as iron castings, aluminum castings, etc.

Complex structural parts: Suitable for making casting molds with complex structures, including inner cavities, special-shaped parts and parts with gaps.

Automobile manufacturing: Sand shell molds used to make casting parts such as automobile engine blocks and cylinder heads.

Aerospace: In the aerospace field, it can be used to make casting molds for aircraft engine parts, etc.

Engineering machinery: Suitable for making casting molds for excavators, bulldozers and other engineering machinery parts.

Energy equipment: Used to make casting molds in energy equipment, such as generator parts, etc.

Casting sand shell forming machines play an important role in the foundry industry. By improving the efficiency and quality of mold making, they help improve the efficiency of the entire casting production line.