Shell core injection machine,Shell mold core shooting machine

Model Z86 series

Products

Products DETAILS

Shell core injection machine,Shell mold core shooting machine

| project | Z8610BF | Z8613B | Z8613BF | Z8615B | Z8615BF | Z8616BF | Z8618B |

| Template size (mm) | 620*300 | 660*330 | 920*320 | 620*400 | 680*420 | 760*460 | 900*600 |

| Maximum core weight (KG) | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Sand bucket volume (KG) | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| heating method | Electric heating | Electric heating | Electric heating | Electric heating | Electric heating | Electric heating | Electric heating |

| Electric heating power (KW) | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| System pressure (Mpa) | 0.55-0.65 | 0.55-0.65 | 0.55-0.65 | 0.55-0.65 | 0.55-0.65 | 0.55-0.65 | 0.55-0.65 |

| Operation method | Manual/Single Week | Manual/Single Week | Manual/Single Week | Manual/Single Week | Manual/Single Week | Manual/Single Week | Manual/Single Week |

Product

Name

Core Shooting Machines

Applied to wach material

casting, metal parts, profiles etc

Applicable industry

machinery, foundry, forging, mechanical and steel industry

function

production sand mould

Voltage

380V/50HZ

or 220V/60HZ

Warranty

One

year

Power

Electricity

Certificate

ISO 9001

Model

Z86

series

PLC

Siemens,Omron

Productivity

Customized

Low

voltage

Schneider

Condition

New

Brands

XiangMao

Color

Customized

Size

Customized

Cleaning method

Automatic

Electrical control system

Auto-detection, auto-alarm and auto-cutout.

Material

Metal/coil

Origin

Shangdong, China

Cleaning material

Shot steel/shot grit/wire cut etc

After-sales service

Engineers available to service machinery

If you have any question or concerns. pls feel free to contact us.

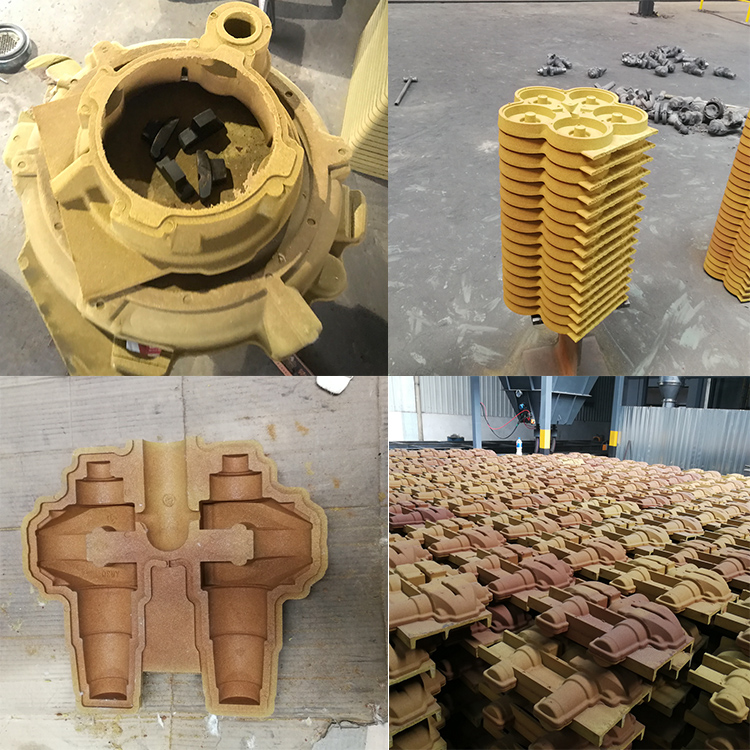

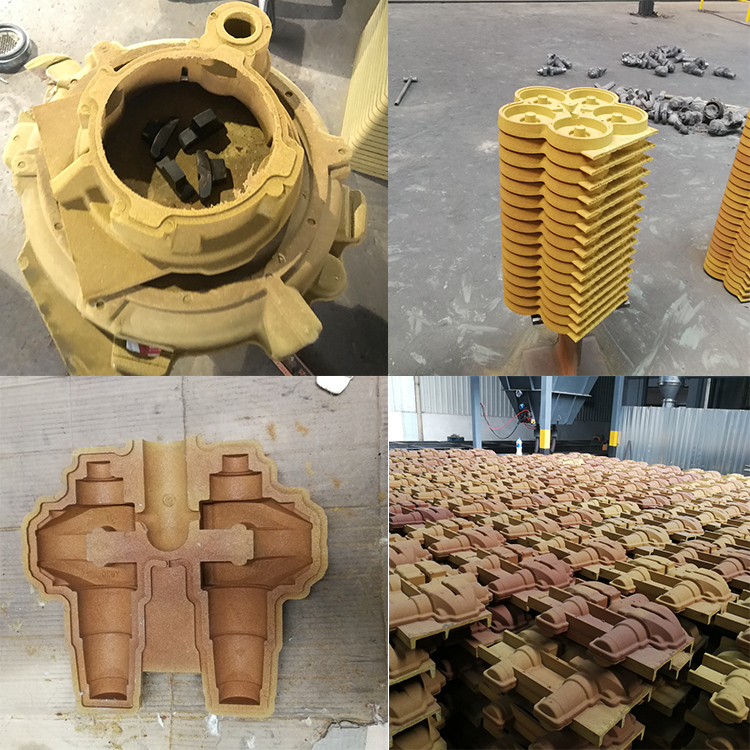

Casting core shooting machines are mainly used to manufacture cores in casting molds. A core shooter is a casting mold with a complex shape and internal cavity. Its function is to form holes or cavities inside the casting during the casting process. The following are some specific product types and their characteristics that casting core shooters are suitable for producing:

Automotive engine blocks and heads:

Features: Complex internal structures, such as combustion chambers, water channels, etc.

Application: Used in the production of cast iron or aluminum alloy cylinder blocks and heads for automotive engines.

Turbine blades:

Features: Requires fine internal cavity and blade structures.

Application: Suitable for manufacturing turbine blades to improve power system efficiency.

Water pump and valve body:

Features: Complex internal channel and valve structure.

Application: Casting molds for manufacturing water pumps, valve bodies and other fluid control equipment.

Pipes and Pipe Fittings:

Features: Internal cavity and complex connection structure.

Application: Suitable for making various pipes, elbows, flanges and other casting molds.

Coolers and Radiators:

Features: Internal heat dissipation channels and sheet construction.

Application: Casting molds for the production of heat exchange equipment such as coolers and radiators.

Hydraulic cylinder block:

Features: Internal oil passage and piston structure.

Application: Suitable for making casting molds for hydraulic system components such as hydraulic cylinder blocks.

Aerospace parts:

Features: Complex internal structure, lightweight design.

Application: Casting molds used to produce aerospace engine parts, spacecraft components, etc.

Motor and generator parts:

Features: Complex internal coil structure.

Application: Suitable for making casting molds for motor casings, generator rotors, etc.

Engineering machinery parts:

Features: Large, thick-walled, internal cavity.

Application: Casting molds for manufacturing construction machinery parts such as excavators and bulldozers.

Customized products:

Features: Complex structures customized according to customer needs.

Application: Suitable for casting molds for various products requiring customized internal structures.

The casting core shooting machine compacts the sand core material to form a core shooting with a complex internal structure, so that castings with specific shapes and internal cavities can be produced during the casting process. This technology is widely used in various industrial fields, providing efficient and precise solutions for the production of castings with complex structures.