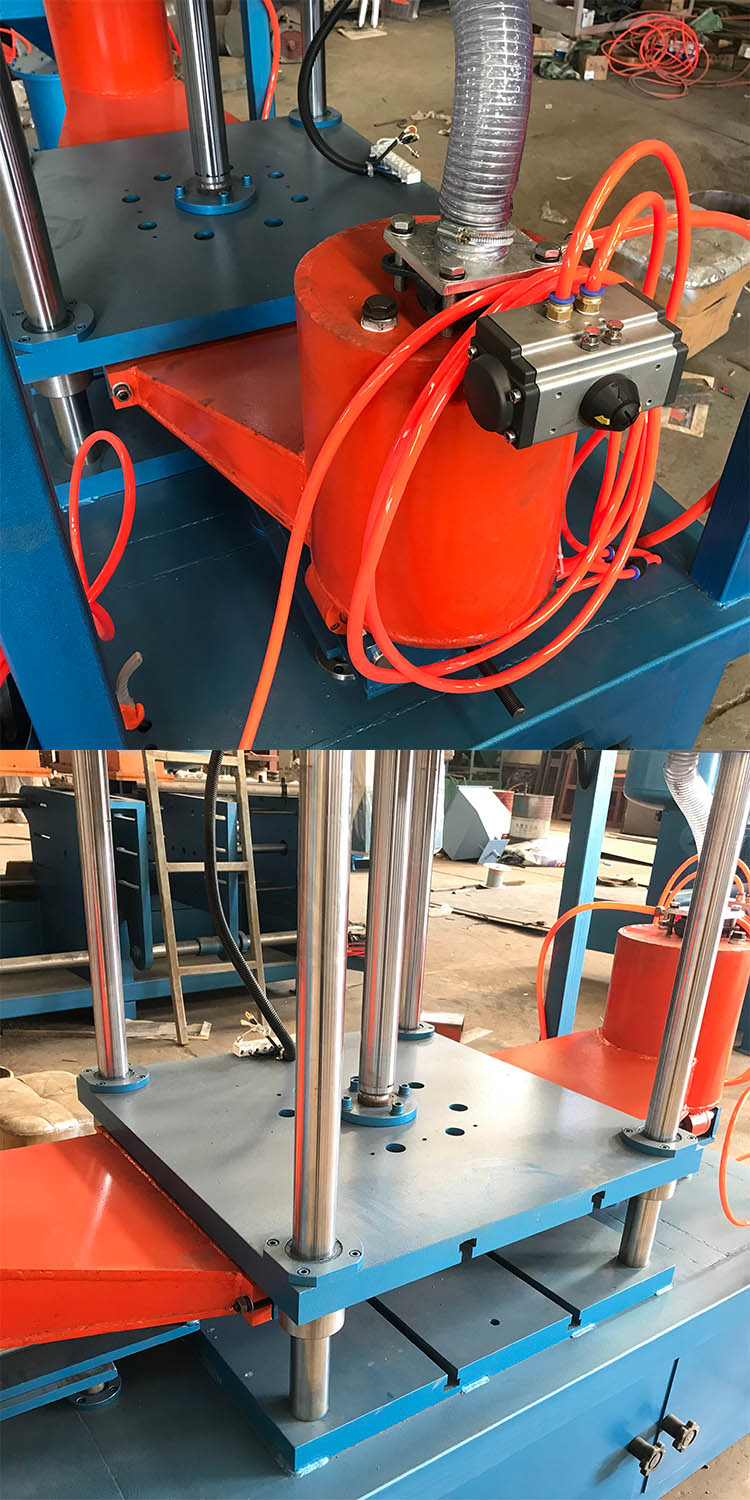

Double-sided sand core shooting machine,Left and right sand core shooting machine

Model ZH 1080-series

Products

Products DETAILS

Double-sided sand core shooting machine,Left and right sand core shooting machine

| NameModel | ZH750 | ZH870 | ZH870B | ZH1080 | ZH1580 |

| template size(㎜) | 780*600 | 930*750 | 930*750 | 1150*950 | 1400*800 |

| Minimum mold thickness(㎜) | 280 | 280 | 280 | 280 | 280 |

| Mold clamping stroke(㎜) | 300 | 300 | 300 | 300 | 500 |

| Maximum sand core weight(㎏) | 20 | 25 | 25 | 35 | 40 |

| Sand bucket volume(㎏) | 200 | 200 | 200 | 300 | 300 |

| heating method | Electric heating/triethylamine | Electric heating/triethylamine | Electric heating/triethylamine | Electric heating/triethylamine | Electric heating/triethylamine |

| Electric heating power(kw) | 25 | 30 | 30 | 45 | 50 |

| How to operate | Manual / Auto | Manual / Auto | Manual / Auto | Manual / Auto | Manual / Auto |

"Double-sided sand core shooting machine" is a core shooting equipment with two-way or bilateral injection function, which is used to prepare sand cores with complex internal structures.

main feature:

Bidirectional injection: This core shooting machine has two injection systems, which can perform bidirectional injection of sand cores simultaneously or alternately. Such a design can improve production efficiency and shorten preparation time.

Bilateral Injection: Core shooting machines may have injection systems on both sides of the machine to handle larger or more complex cores. This configuration is also able to accommodate parts of different shapes and sizes.

Automated control: It has an advanced automated control system that can control injection parameters and time through preset programs to ensure the consistency and stability of the production process.

High precision: Bidirectional or bilateral injection systems are usually designed with high precision to ensure that the shape and size of the sand core meet design requirements.

Synchronous work: If there are multiple stations, the injection systems at different stations can work synchronously to prepare multiple sand cores at the same time.

Bilateral operation: The symmetrical design allows injection on both sides of the equipment, suitable for symmetrical or similar sand cores.

Automatic switching: The core shooting machine can have an automatic switching function, and can choose to use one-way injection, two-way injection or double-sided injection according to production needs.

Real-time monitoring: The control system can monitor various parameters during the injection process in real time to ensure the accuracy and consistency of the injection.

Such equipment may be more efficient in the preparation of complex parts because it can handle sand cores of different shapes and sizes more flexibly while increasing the speed and efficiency of production.