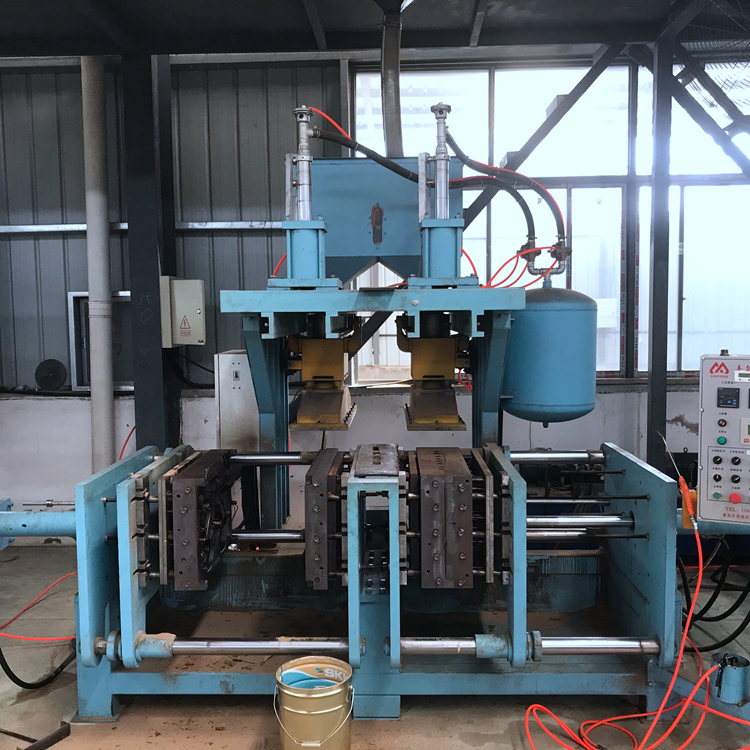

Vertical parting boxless injection molding machine and horizontal parting boxless injection molding machine

Upload Time:

Jan 28, 2024

The injection molding machine uses compressed air to evenly inject the molding sand into the sand box for pre-tightening, and then applies pressure for compaction. Commonly used are vertical parting boxless injection molding machines and horizontal parting boxless injection molding machines. The vertical splitting boxless injection molding machine does not use a sand box for modeling. The molding sand is directly injected into the molding chamber with a template. The size of the sand mold produced is high. There are cavities on both sides of the sand box. The productivity is high, but the core setting is difficult and the molding sand is Strict quality requirements. The horizontal parting and unboxing injection molding machine uses a sand box for molding. After the sand mold is built, it is closed and unboxed. It is convenient to set the core and has high productivity.

The core shooting machine uses coated sand to make cores and is suitable for both hot core boxes and cold core boxes. The characteristic of the core shooting machine is that it uses two guide pillars, opens and closes the mold vertically, and installs two different molds at the same time. The middle fixed frame can be installed with a fixed mold on both sides, and the mold can be opened and closed on the left and right (equivalent to a double mold frame). Core shooting machines are widely used in the foundry industry. The cores produced by core shooting machines have precise dimensions and smooth surfaces. The working principle of the core shooting machine is to inject the core sand mixture with liquid or solid thermosetting resin as the binder into the heated core box. The sand core is preheated in the core box and quickly hardens to a certain thickness (about 5 ~ 10 mm)

Core shooting machines have been widely used in recent years, because the use of core shooting machines can save high wages for molding workers. Because multiple boxes are stacked for pouring, it can also reduce the waste of pouring risers. The coated sand after pouring has good disintegration properties, which is conducive to sand cleaning. The core shooting machine has high production efficiency and accurate sand mold size, which can appropriately reduce the processing amount; it is easy to operate and has a high casting yield. More foundries prefer to use core shooting machines for molding.

Features

The Z.86F series core shooting machine shoots sand cores and shapes vertically. The whole machine structure mainly consists of four major parts.

1. Column components: Mainly composed of cross beams and columns, which constitute the upper structure of the equipment. Sand cylinders, sand hoppers, sand valve components, compression cylinders and other components are installed on the beams to form the sand supply and air supply system for core making.

2. Sand shooting device: It consists of sand barrel, air valve, sand barrel frame, shooting head, sand shooting plate and other parts. During operation, the sand barrel is pressed by the compression cylinder on the upper plane of the core box, and the sand injection valve is opened for sand injection. After the exhaust and sand injection are completed, loosen the compression cylinder (return to the original position) to complete the sand injection and sand adding work.

3. Mold base components: mainly composed of movable template, left and right support plates, guide posts, guide bushes, ejector pins, mold clamping cylinders and other components.

3.1 The entire mold base is installed on the base by the left and right bracket plates.

3.2 The movable template moves left and right along the guide pillar under the push and pull of the mold closing to complete the core making process of mold closing and mold opening. When the movable template is opened, the ejector pin on the fixed template is pushed against the ejector core plate to eject the sand core, which can be easily removed by hand.

3.3 Base: The support of the entire equipment, mold frame, columns, electric control box, solenoid valve, etc. are installed on it.

Relevant News